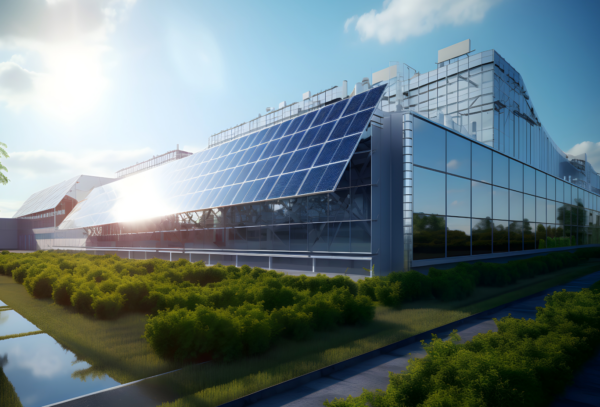

The manufacturing industry, once a behemoth of pollution and resource consumption, is undergoing a dramatic transformation. Driven by increasing consumer awareness, regulatory pressures, and technological advancements, the future of manufacturing is undeniably sustainable. At Kickr Design, we believe that sustainable manufacturing is not just a trend but a necessity and a competitive advantage.

A Shift in Paradigm

For decades, the focus of manufacturing was on efficiency and cost reduction. While these factors remain crucial, they are now being complemented by a strong emphasis on environmental responsibility and social impact. Sustainable manufacturing involves producing goods in a way that minimizes environmental damage, conserves resources, and improves the lives of workers and communities.

Key Trends Shaping the Future

Several key trends are driving the shift toward sustainable manufacturing:

- Circular Economy: The linear model of “take, make, dispose” is being replaced by a circular economy where products are designed for reuse, repair, and recycling. This approach minimizes waste and reduces the demand for raw materials.

- Advanced Materials: The development of new, sustainable materials is revolutionizing the manufacturing industry. From bio-based plastics to recycled composites, these materials offer improved performance and reduced environmental impact.

- Digital Transformation: Technology is playing a crucial role in driving sustainability. Digital tools can optimize production processes, reduce energy consumption, and improve supply chain transparency.

- Consumer Demand: Consumers are increasingly conscious of the environmental impact of the products they buy. Companies that prioritize sustainability are more likely to attract and retain customers.

Kickr Design’s Role in Sustainable Manufacturing

At Kickr Design, we are committed to helping our clients create products that are both innovative and sustainable. Our approach involves:

- Design for Sustainability: We incorporate sustainability principles into the product design process from the outset. This includes material selection, energy efficiency, and end-of-life considerations.

- Lean Manufacturing: By eliminating waste and optimizing processes, we help our clients reduce their environmental footprint and improve profitability.

- Supply Chain Management: We work closely with our clients to ensure that their supply chains are ethical and sustainable. This includes sourcing materials from responsible suppliers and minimizing transportation emissions.

The future of manufacturing is bright. By embracing sustainability, companies can not only reduce their environmental impact but also gain a competitive advantage, build brand reputation, and contribute to a more sustainable future.