Salt Grinder

The Infinity Salt Air Machine provides a highly effective treatment in as little as 3-5 minutes. Salt particles reach deep into the lungs and sinuses providing instant relief. Weighing in at just 2.5 lbs. and 7 inches tall, this personal salt machine can travel with you almost anywhere and provides salt therapy on the go whenever you need it. Use it overnight at home or when traveling for an amazing night’s sleep that clears the sinuses and lungs.

InfinitySaltAir.com

The Development Process

Product Purpose

Salt is used…

Scale and Interface

Initially the product…

Engineering Technology

The first prototype …

Prototype Fabrication

During the course of development …

The Client

Anne Glasgow owned a salt therapy studio and had generated the idea to sell a consumer product salt grinder that people could use at home that was small enough for a consumer product while also having the capability to precisely grind salt to the ideal micron sized pieces for salt therapy. Most salt grinders were large and bulky but more importantly they didn’t grind the salt to a fine enough micron particle size that was optimal for salt therapy.

The Challenge

The high level goal of the project was to take Anne from idea to small batch manufacturing so she could get her salt grinder diffuser idea onto the market and start generating revenue. The key goals for her consumer product salt grinder were to make it intuitive, small/portable device with the capability to grind salt to a precise size optimal for salt therapy that could go airborne through the built in distribution system. Producing a salt grinder for salt therapy posed unique challenges. Achieving precision to grind salt into optimal micron-sized particles required advanced engineering. Executing small-batch manufacturing cost-effectively while ensuring consistent quality added complexity. Additionally, miniaturizing existing industrial salt grinding devices without compromising performance demanded innovative design and material solutions. Balancing these technical, economic, and scale constraints was critical to delivering a compact, high-quality product tailored for therapeutic use.

The Solution

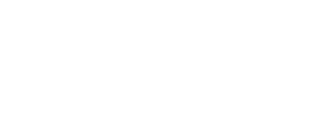

- Concepting

- We created several concepts of look and feel as well as different methodologies of achieving the desired micron particle size.

- Identification of highest risk design elements (achieving the correct particle size consistently).

- Creation of the functional specifications Anne was working to achieve.

- Design and Risk Reduction

- We wanted to make sure we took the most cost effective development route so the first thing we focused on was de-risking the high risk item of achieving the correct particle size in a consumer sized/priced product. We did this through just focusing on designing the grinding chamber and then proceeded to test and iterate on this until we had a subsystem that achieved Anne’s goals.

- Once we had a solid solution for achieving Anne’s particle size we build the rest of the system around the salt grinding chamber.

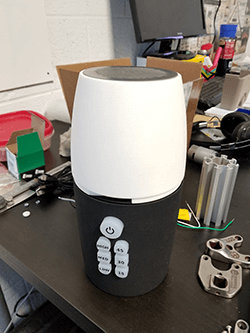

- Prototyping

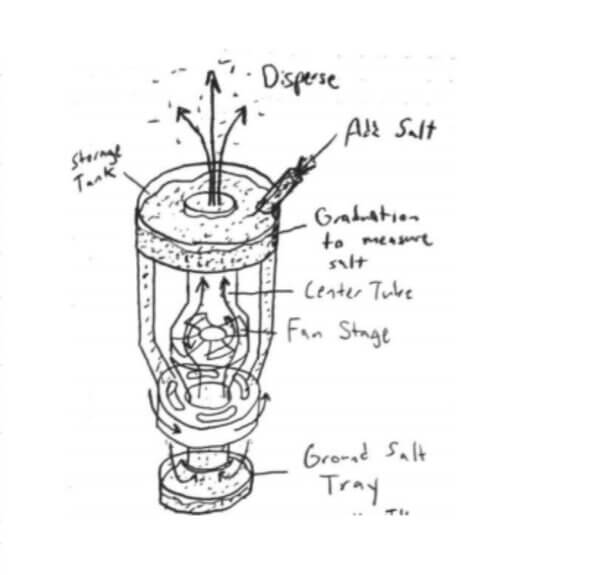

- With the full design ready we built the first prototype to determine what aspects worked well and which needed iteration.

- After a few quick prototype iterations we arrived on a design that everyone was excited about and locked in a prototype design freeze.

- DFM and Prep for Manufacturing

- We took the design through a thorough review to make the small updates needed for a small manufacturing run that enables us to make tooling for the sheet metal, plastic, PCB, and urethane parts.

- We prepped the quality control checks and documentation that would be needed for a successful manufacturing run.

- Manufacturing

- We worked with our manufacturing partners to create the individual parts and did the final assembly of the units right here at Kickr!

- Quality Control

- We performed the detailed quality control on all units to ensure a high quality product for Anne.

The Results

For this project the suite of services combined was a huge value to this customer because she was able to go from idea to prototyping all the way to manufacturing without having to spend extra time or money doing it herself or switching vendors. The final delivery from Kickr Design was the first run of 450 manufactured units. After we helped the client with their first manufacturing order they felt ready to take on manufacturing themselves and have partnered with a vendor to manufacture and iterate on their units. It was a rewarding experience getting to see the customer test the unit they’d been dreaming of for the past few years for the first time.

Let’s bring your project to life!

You bring the vision, we’ll bring the resources to help you build it!

We are always happy to walk you through all your options and help you make informed decisions throughout your product development journey. We know timelines, goals and needs can even change during a project, and pride ourselves on our deep understanding and real-time flexibility to pivot with you when necessary.

Fill out the form for your free cost estimate.

"*" indicates required fields