Delamite

The Delamite is a unique way of unclogging sinks and plumbing with the use of a vaccum. The product will allow users a non-invasive and chemical free way to do the job with more consistent pull than a plunger, and with less physical effort to boot!

The Development Process

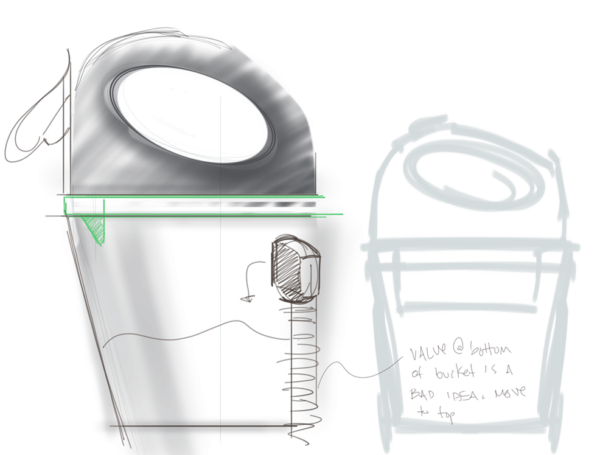

General Concept

Kickr Design put together concept sketches based on Adonis’s size constraint requirements.

Custom Electronics

Here the Kickr EE team worked together with mechanical engineering and industrial design for a well placed electronics package safe from water transfer.

Mechanical Engineering

The vacuum motor was specified by the mechanical engineers to have the right fit and power for the application.

Prototype Fabrication

Using 3D printing, silicone molding, and some traditional hand craft work, a finished prototype was produced for applications testing.

The Client

Adonis Elam desired to create a prototype of his drain clog removal invention with a consumer facing aesthetic. When the project came to Kickr Design, the objective was well defined as to how the product was to be configured, “…in general aspects of size, shape, and materials, resemble a hand-held, canister-style vacuum cleaner…would measure approximately 15 to 18 inches in length and 8 inches in diameter…”. The Delamite would be a powered vacuum used to suck clogs or lost objects out directly out of a drain in a sink basin.

The Challenge

Adonis wanted to develop a prototype to allow for testing and refinement. We built a custom housing and hose attachments to allow us to test the idea fully. Developing an electronic circuit board from scratch required a little bit of bring up time. The requirement for this device to work on different sinks of all types meant that we had to explore different hose ends to allow for different types of sink geometry. There was a challenge around addressing the need for electronics in a context that involved standing water. The filtration solution also required some iteration.

The Solution

- Concept exploration – creation of the form factor appropriate to the use-case, this was the domain for industrial design.

- Electrical engineering – custom board layouts and PCB assembly.

- Mechanical engineering – sink interface adapters had to be design specifically for an effective vacuum seal on standard drain sizes.

- Iterative modeling – low to medium fidelity study models were created to validate human factors design decisions in CAD.

- Prototype fabrication – silicone molding, 3D printing, assembly and testing all under one roof!

- Aesthetic color studies

The Results

The project is still in development, but is close to a design freeze for the manufacturing documentation phase. Kickr Design has produced a design for manufacture plan to segue the product from R&D prototype to a mass produced consumer model.

Let’s bring your project to life!

You bring the vision, we’ll bring the resources to help you build it!

We are always happy to walk you through all your options and help you make informed decisions throughout your product development journey. We know timelines, goals and needs can even change during a project, and pride ourselves on our deep understanding and real-time flexibility to pivot with you when necessary.

Fill out the form for your free cost estimate.

"*" indicates required fields