Coolspine – spinal temperature control device

Cryolife approached us with an ambitious idea aimed at significantly improving surgical outcomes: a device to cool the spinal cord during surgeries where blood flow is reduced for extended periods. This cooling process is crucial in minimizing the risk of paralysis, a common and severe complication in such surgeries. While Cryolife had extensive experience with implants, they lacked the in-house engineering capabilities required to develop the complex electrical, mechanical, and software systems for a fluidic chiller.

The Solution

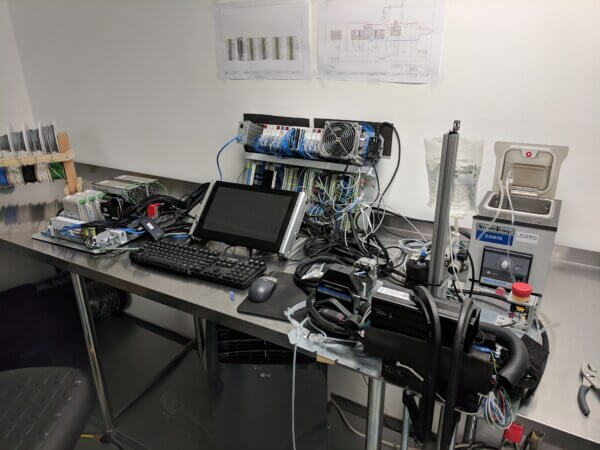

Starting with Cryolife’s trilumen catheter design, which is intended to be introduced into a patient’s spinal canal, we embarked on a comprehensive design and development process. Our goal with Coolspine was to create a custom prototype fluidic rig for in vitro testing and animal evaluation.

Key Development Phases:

- Fluid Mechanics and Thermal Performance Calculations: We began by performing detailed calculations on fluid mechanics and thermal performance to size the pumping and thermal systems accurately. This foundational step ensured that the system could deliver the necessary cooling efficiently and reliably.

- Prototype Development and Testing: We designed and built a custom prototype fluidic rig. This included setting up experiments with actual components to gather data, allowing us to iterate and optimize component selection and sizing.

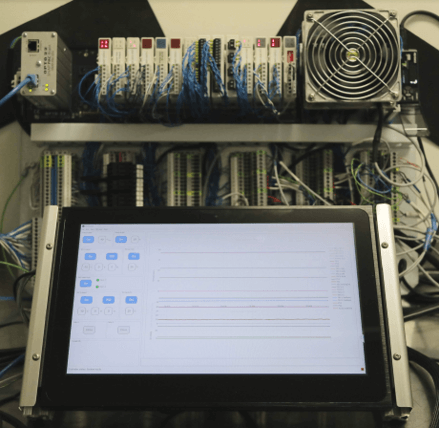

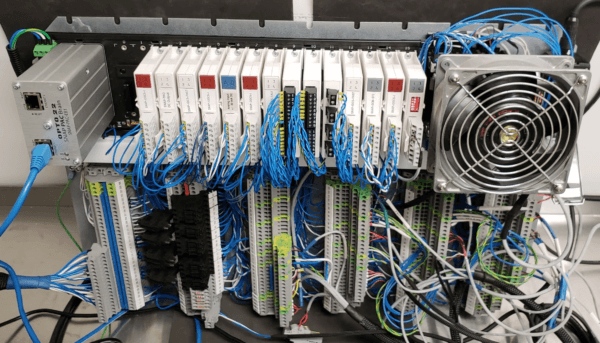

- Component Integration: Our solution featured several sophisticated components:

- Peristaltic Servo Pump: This pump circulates chilled saline through the catheter, providing consistent cooling.

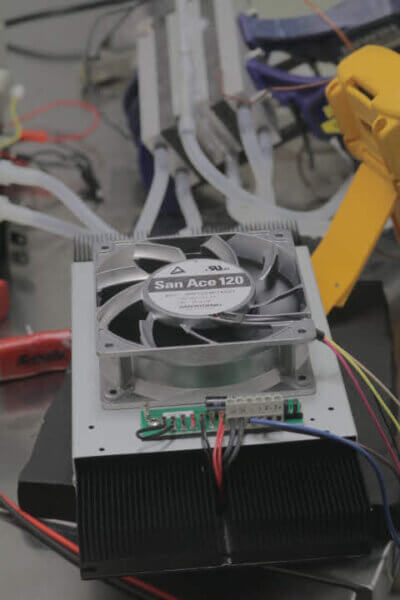

- Heat Exchanging System: A unique fluid-fluid-air heat exchanger coupled with high-powered thermoelectric coolers ensures effective temperature control.

- Pressure Transducers and Thermistors: These sensors measured pressures at the catheter inlet and outlet, and monitored temperatures throughout the system.

- Custom Software Development: We developed a custom software solution to control the system and visualize sensor and control parameters in real-time. This software was crucial for testing and refining the prototype, allowing for precise adjustments and improvements.

The Outcome

The collaboration with Cryolife culminated in Coolspine: a robust, functional prototype that underwent rigorous in vitro and animal testing. The innovative cooling system showed promising results in reducing the risk of paralysis during surgeries with prolonged reduced blood flow.

Cryolife’s vision, combined with our engineering, has paved the way for potential advancements in surgical procedures and patient outcomes. This project underscores our commitment to pushing the boundaries of what’s possible, providing tailored solutions that address complex challenges in the medical field.

Looking Forward

We continue to seek out and embrace challenging projects that demand ingenuity and technical expertise. Our partnership with Cryolife and the success of the Coolspine project is a testament to our ability to deliver cutting-edge solutions that make a real difference.

Find more information on our projects here, and if we can help bring your innovation to life, contact us today!

Let’s bring your project to life!

You bring the vision, we’ll bring the resources to help you build it!

We are always happy to walk you through all your options and help you make informed decisions throughout your product development journey. We know timelines, goals and needs can even change during a project, and pride ourselves on our deep understanding and real-time flexibility to pivot with you when necessary.

Fill out the form for your free cost estimate.

"*" indicates required fields